LJ Metal also provides on-site inspection and other fabrication services. We aim to provide outstanding customer services by taking care of even the smallest order with rich experience in providing pipe and accesseries.

LJ Metal offers on-site inspections and loading supervision before shipment for stainless steel, alloy materials. With our dedicated services you could make sure every detail and every stage of your orders be no problem. We could be your local eyes and hands with efficiency to save your cost and time, and our charge will be very reasonable.

LJ Metal provide pre-fabrication services as flange connection, welding, bending, painting, bevelling for end users in Chemical industies, Petrochemical Industries, Pharmacy Industries, Oil and Gas Industries, Shipbuilding Industries.

LJ Metal provides U bending service, heat treatment for u bend and hydraulic testing is very important for u tubes, we could provide 100% hydraulic test for bended tubes, as well as the heat treatment and pickling after bending.

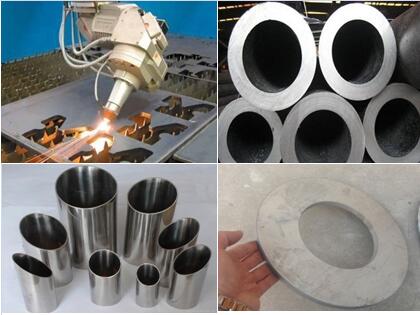

LJ Metal also supply cutting services for pipes and plates, fully Automatic Saws and laser cutting could cut any shape and length.

LJ Metal provide polishing services for pipe and fittings both inside and outside, our mechanical polishing could achive 400 grit surface, and electrolytic polishing could achive more harsh surface condition requirement for food and bevarage industries.

LJ Metal also provide non-standard special parts as special coupling, elbow, flanges, connections.

We are proud to be involved in many projects all over the world, and we are honour to have supplied safe and reliable materials to numurous customers.

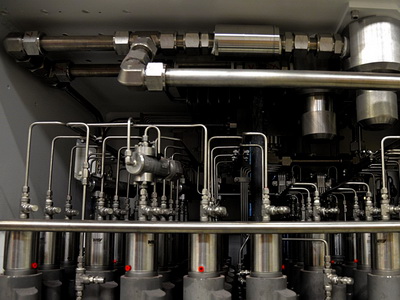

Large diameter stainless steel or alloy pipe and tubes are usually used in petrochemical plants as Olefin plants, Fertilizer plants.

Pipes used in power plant have to withstand high temperatures and high pressures.

Industrial boilers and heat exchangers require lots of stainless steel tubing.

TP316L pipe and duplex stainless steel pipe are widely used for offshore platform to resist the sea water corression.